Textile Industry Zone, East Hutang Town, Wujin District,213100 Changzhou,China

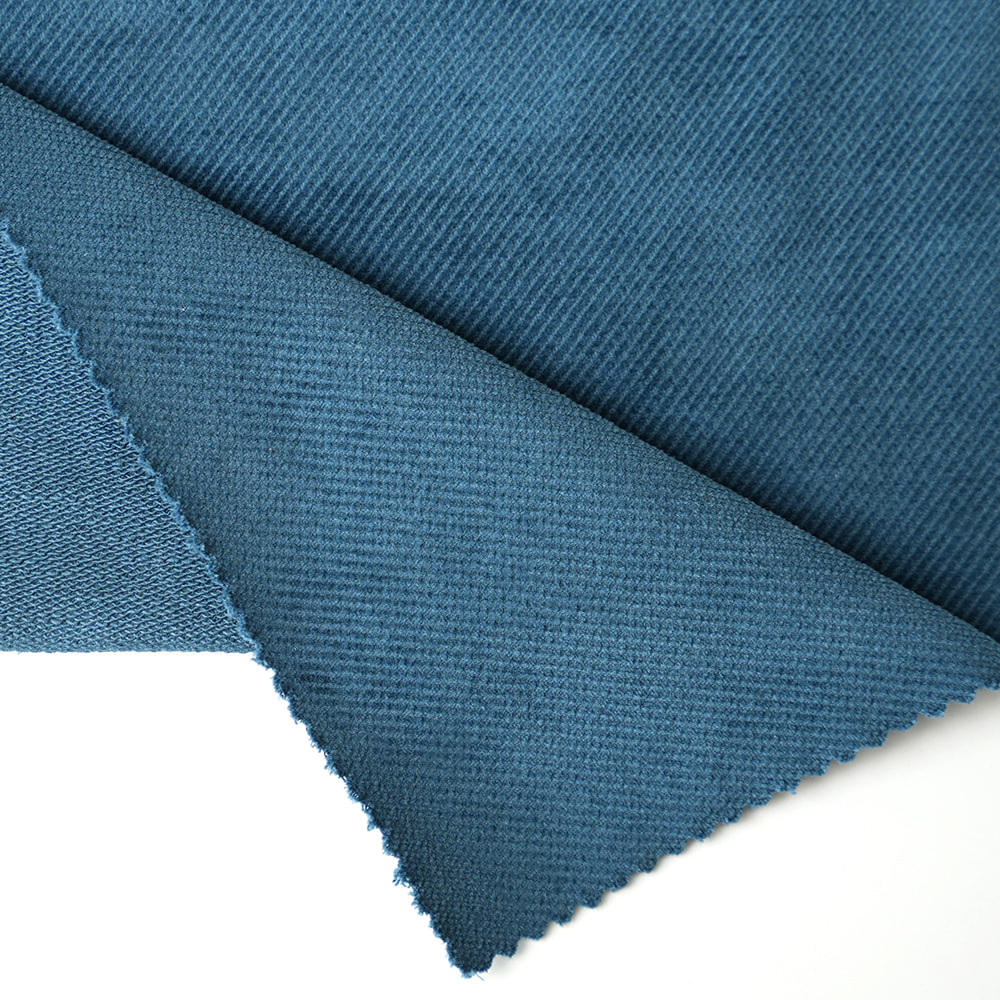

Corduroy fabric is widely appreciated for its distinctive ribbed texture, durability, and classic aesthetic, commonly used in apparel, home textiles, and fashion accessories. Among the variations of corduroy, double weave corduroy fabric has gained attention for its enhanced strength, thickness, and luxurious feel. One of the key performance attributes of double weave corduroy is abrasion resistance, which determines its longevity, usability, and suitability for different applications. Understanding how abrasion-resistant this fabric is can help manufacturers, designers, and consumers make informed choices.

1. Structure of Double Weave Corduroy

Double weave corduroy differs from traditional single-layer corduroy due to its dual-layer construction:

- Two interwoven layers of fabric provide extra thickness and stability.

- Raised ribs (wales) on the surface create the characteristic corduroy texture, but in double weave corduroy, the base layer adds reinforcement.

- This construction enhances the fabric’s ability to resist wear, as the load from friction is distributed across both layers rather than concentrated on a single layer.

The structural advantage of double weave corduroy is one of the main reasons it exhibits higher abrasion resistance than standard corduroy fabrics.

2. Factors Affecting Abrasion Resistance

The abrasion resistance of double weave corduroy fabric is influenced by several factors:

-

Yarn Quality:

- High-strength cotton, polyester blends, or synthetic fibers improve resistance to surface wear.

- Long-staple cotton or combed yarns produce a smoother, denser fabric that resists pilling and fiber breakage.

-

Fabric Density and Weight:

- Heavier fabrics with tightly woven bases are less prone to thread breakage under friction.

- The double weave structure increases thread density, enhancing durability and abrasion performance.

-

Pile Height and Width (Wales):

- Narrower wales generally experience less friction per ridge and maintain their appearance longer.

- Shorter pile heights reduce the likelihood of fibers bending, fraying, or flattening, which improves long-term abrasion resistance.

-

Finishing Treatments:

- Mercerization, singeing, or protective coatings can increase surface smoothness, reduce fiber fuzz, and enhance resistance to repeated wear.

- Anti-pilling treatments prevent small fibers from loosening under friction.

3. Testing Abrasion Resistance

The Martindale or Wyzenbeek test is commonly used to measure textile abrasion resistance. These tests simulate repeated rubbing or wear under controlled pressure:

- Martindale Test: Fabric is rubbed in a circular motion under a set load until visible wear appears.

- Wyzenbeek Test: Fabric is rubbed back and forth over a wire mesh for a defined number of cycles.

Double weave corduroy often shows significantly higher cycle counts before wear appears compared to single-layer corduroy. Depending on yarn type, pile construction, and finishing, high-quality double weave corduroy can withstand tens of thousands of abrasion cycles, making it suitable for garments or upholstery subject to heavy use.

4. Applications Requiring Abrasion Resistance

Because of its strong abrasion resistance, double weave corduroy fabric is ideal for applications where durability is critical:

- Apparel: Pants, jackets, skirts, and outerwear that experience frequent friction and movement benefit from double weave corduroy.

- Home Textiles: Upholstery, cushion covers, and heavy drapes require fabrics that can withstand repeated contact and cleaning.

- Bags and Accessories: Backpacks, handbags, and footwear benefit from the strength and wear resistance of double weave corduroy.

The combination of comfort, aesthetic appeal, and durability makes it a versatile fabric across fashion and interior design sectors.

5. Comparison with Other Fabrics

When compared with other common fabrics:

- Single-Layer Corduroy: Lower abrasion resistance due to less structural reinforcement and thinner base fabric.

- Denim: Denim is generally very abrasion-resistant, but double weave corduroy can match or exceed its wear performance depending on the finishing and fiber blend.

- Velvet or Velour: These fabrics have a softer pile but tend to wear faster; double weave corduroy offers better longevity under friction.

This shows that double weave corduroy balances texture, comfort, and durability, which many alternative fabrics may not achieve simultaneously.

6. Maintenance for Longevity

Even with high abrasion resistance, proper maintenance ensures long-term performance:

- Gentle Washing: Avoid harsh detergents and high-speed machine washing that can stress the fibers.

- Minimize Friction: Prevent excessive rubbing against rough surfaces to maintain pile integrity.

- Regular Brushing: Use soft brushes to lift fibers and maintain appearance without damaging the fabric.

- Avoid Prolonged Sun Exposure: UV rays can weaken fibers and reduce abrasion resistance over time.

By following these maintenance practices, the abrasion resistance of double weave corduroy can be preserved for years.

Conclusion

Double weave corduroy fabric is highly abrasion-resistant due to its dual-layer construction, dense yarns, and durable pile structure. Factors such as yarn quality, pile height, finishing treatments, and proper maintenance all contribute to its durability. Compared with single-layer corduroy, velvet, or some woven fabrics, double weave corduroy offers superior resistance to wear, making it ideal for high-use apparel, upholstery, and accessories.

Its combination of aesthetic appeal, comfort, and long-lasting durability has made double weave corduroy a popular choice for both fashion and interior applications, proving that it is not only stylish but also practically resilient.